Selection Process

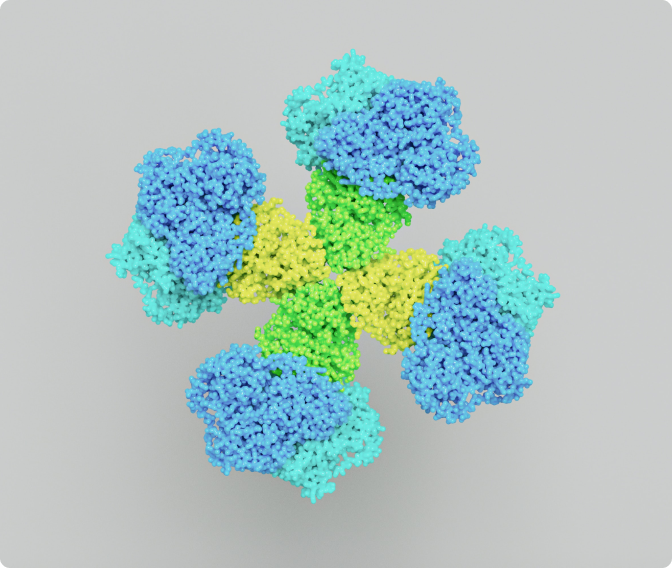

Return activated sludge (RAS) or waste activated sludge (WAS) flows into the sludge selector at a controlled speed along the tangent. Inside the selector, the mixed liquor undergoes rotational motion due to centrifugal force and the inner wall of the device. Heavier particles experience stronger centrifugal force, causing them to be propelled towards the wall and spiral downward, forming densified sludge that returns to the biological reaction tank. Lighter sludge particles and filamentous sludge tend to move upward along the axis and are discharged through the overflow port into the sludge concentration tank. Through prolonged selection, loosely bound filamentous bacteria and other lightweight sludge components are continuously removed, allowing denser sludge to accumulate and eventually forming densified or granular sludge.

EN

EN